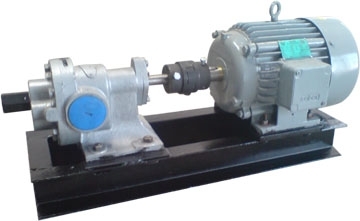

Industrial Rotary Gear Pump

Product Details:

- Inlet/Outlet 1 to 4 BSP

- Theory Rotary Gear Pump

- Max Suction Up to 6 meters

- Head Size Up to 100 meters

- Control System Manual/Automatic

- Voltage 230V/415V

- Caliber Standard

2000 INR/Unit

X

Industrial Rotary Gear Pump Price And Quantity

- 2000 INR/Unit

- Direct Coupled / Belt Driven

- Standard

- Yes

- Air Cooled

- Threaded / Flanged

- Up to 100,000 cst

- Liquid Only

- Powder Coated / Painted

- Long Service Life

- Viscous Liquids, Lubricating Oil, Vegetable Oil, Syrups

- Clockwise/Counter Clockwise

Industrial Rotary Gear Pump Product Specifications

- Up to 6 meters

- Electric

- Up to 100 meters

- Mechanical Seal

- Rotary Gear Pump

- 1 to 4 BSP

- Positive Suction

- Up to 12000 LPH

- 230V/415V

- Cast Iron/SS316

- Oil, Viscous Fluids, Chemical Industries

- Manual/Automatic

- Up to 10 bar

- Up to 200 LPM

- Standard

- -10C to 120C

- Low

- Industrial Fluid Transfer

- Single/Dual Gear

- 50 Hz/60 Hz

- Foot/Self Mounting

- IS & DIN

- 0.5 HP to 10 HP

- Leak Proof, Heavy Duty Construction, Easy Maintenance

- Rotary Gear

- Up to 10 bar

- 1440 RPM

- Self Priming

- Direct Coupled / Belt Driven

- Standard

- Yes

- Air Cooled

- Threaded / Flanged

- Up to 100,000 cst

- Liquid Only

- Powder Coated / Painted

- Long Service Life

- Viscous Liquids, Lubricating Oil, Vegetable Oil, Syrups

- Clockwise/Counter Clockwise

Product Description

Supported by a team of diligent professionals, we have been able to manufacture and supply pristine quality Industrial Rotary Gear Pump. Widely used in industries, this pump is highly appreciated for its perfect finish. Offered pump is manufactured with utmost perfection by making use of optimum quality components and advanced machinery in tune with market norms. Additionally, we provide this Industrial Rotary Gear Pump in different specifications to meet the need of clients.

Major Key Features:

- Easy to operate

- Sturdy construction

- Noise-free operation

- Require less maintenance

Specification

| Application | Commercial, Industrial |

| Speed | Up to 1500 rpm |

| Pressure | 30kg/cm2 |

| Voltage | 220 to 380 V |

| Max Flow Rate | 20 LPM |

Versatile Applications and Reliability

Built to handle demanding industrial requirements, this rotary gear pump excels in the transfer of viscous fluids and lubricating oils across oil, chemical, and food processing industries. The pumps heavy-duty construction, positive suction, and self-priming capabilities guarantee dependable operation, even under challenging conditions. It suits both direct coupled and belt-driven setups, providing installation flexibility for various industrial flow needs.

Efficient Design and Easy Maintenance

Engineered for ease of use, the pump features manual or automatic control options and leak-proof mechanical seals. Its single or dual gear configuration minimizes noise and vibration. With standard body thickness, foot or self-mounting options, and ready-to-fit replacement parts, maintenance remains straightforward and cost-effective, ensuring minimal downtime during routine servicing or repairs.

FAQs of Industrial Rotary Gear Pump:

Q: How does the Industrial Rotary Gear Pump handle highly viscous liquids?

A: The pump utilizes precisely machined rotary gears and a positive suction mechanism to manage fluids with viscosities up to 100,000 cst. Its robust construction, along with options for threaded or flanged port connections, ensures efficient transfer of thick fluids without clogging or loss of performance.Q: What types of industries and applications is this pump most suited for?

A: This gear pump is ideal for oil refineries, chemical processing plants, food processing units (handling syrups and vegetable oils), and various other industries requiring consistent transfer of viscous liquids. Its ability to operate within -10C to 120C and manage liquids only makes it especially reliable in industrial environments.Q: When is it necessary to perform maintenance on the rotary gear pump, and how is it managed?

A: Routine maintenance is recommended based on operating hours and fluid type, typically after prolonged high-viscosity operations. Maintenance involves checking seals, inspecting gears, and, if necessary, replacing readily available parts. The pump is designed for easy access, supporting efficient upkeep with minimal operational interruption.Q: Where can this pump be installed, and what are the available mounting options?

A: Installation is flexible, with mounting options including foot or self-mounting. Its compact design permits deployment in confined industrial spaces, and it can be integrated into both new and existing fluid transfer systems, provided there is compatibility with power supply (230V/415V) and port sizes (1 to 4 BSP).Q: What benefits does the leak-proof design and mechanical seal offer?

A: The mechanical seal and leak-proof design prevent fluid leakage, safeguard pump internals from contamination, and extend service life. This ensures reliability in continuous operations, reduces risk of environmental spills, and minimizes maintenance frequency.Q: How does the priming and suction process work for this pump?

A: The rotary gear pump is self-priming, which means it can automatically evacuate air from the suction line, creating the necessary vacuum to draw fluid up to 6 meters. This feature greatly simplifies installation and start-up, especially when handling viscous or hard-to-transfer liquids.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email