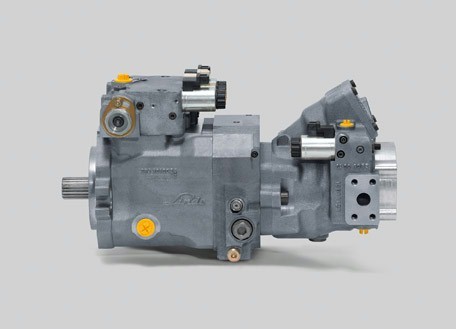

Heavy Duty Hydraulic Pump

Product Details:

- Fuel Tank Capacity N/A (Electric powered)

- Speed 1450 RPM

- Inlet/Outlet 1 Inch / 1 Inch BSP Thread

- Mounting Type Foot Mounted

- Flow Rate 120 L/min

- Features Robust Design, High Efficiency, Corrosion Resistant

- Working Temperature -10C to 80C

10000 INR/Piece

X

Heavy Duty Hydraulic Pump Price And Quantity

- 10000 INR/Piece

- 32 kg

- Threaded

- IP55

- Clockwise

- Easy Maintenance

- Hydraulic Oil, Light Mineral Oil

Heavy Duty Hydraulic Pump Product Specifications

- Manual Control

- Max 210 Bar

- Electric Motor Driven

- 50 Hz

- Heavy Duty Cast Iron and Stainless Steel

- -10C to 80C

- Industrial and Agricultural

- 210 Bar

- Heavy Machine, Hydraulic Systems, Construction

- Medium Duty Caliber

- 35 M

- 220-240 V

- Upto 120 LPM

- Below 72 dB(A)

- Hydraulic Pump Theory

- 7 Meters

- Single Stage

- N/A (Electric powered)

- 1450 RPM

- Self Priming

- 2.5 HP

- Foot Mounted

- 1 Inch / 1 Inch BSP Thread

- Robust Design, High Efficiency, Corrosion Resistant

- Heavy Duty Hydraulic Pump

- 120 L/min

- Automatic Suction

- ISO 9001:2015 Certified

- High Performance Nitrile Seals

- 32 kg

- Threaded

- IP55

- Clockwise

- Easy Maintenance

- Hydraulic Oil, Light Mineral Oil

Product Description

Fostered with years of hard work and industrial experience, we are able to provide pristine quality Heavy Duty Hydraulic Pump. Our team of experts manufacture this pump with utmost perfection by making use of latest machinery using optimal quality components and cutting-edge machinery in accordance with set quality norms. This pump finds wide application in chemical, pharmaceutical and other industries. Our clients can purchase this Heavy Duty Hydraulic Pump from us in both standard as well as customized options.

Major Key Features:

- User friendly design

- Sturdy construction

- Excellent performance

- Longer service life

Specification

| Frequency | 50-60 hz |

| Pressure | 20/16 Mpa |

| Usage | Industrial, Commercial |

| Voltage | 220-240v |

Outstanding Efficiency and Performance

This hydraulic pump combines a sturdy construction with advanced hydraulic theory, optimizing fluid movement for maximum efficiency. It boasts a powerful 2.5 HP motor, a medium-duty caliber, and operates at a consistent speed of 1450 RPM, guaranteeing reliable performance even under continuous, heavy workloads. Its self-priming and automatic suction features ensure a seamless start, making it ideal for rapid deployment in industrial and agricultural settings.

Designed for Tough Environments

Built with corrosion-resistant materials and protected to IP55 standards, the pump withstands challenging conditions, from dust-laden environments to temperature extremes between -10C to 80C. High performance nitrile seals and threaded 1-inch BSP connections further enhance its durability, making maintenance straightforward and minimizing downtime during prolonged operations.

User-Focused Maintenance and Operation

Ease of use is integral to this pumps design. Manual control and foot mounting simplify installation and daily operation. Comprehensive serviceability means the pump requires minimal intervention, ensuring operators can maintain long-term productivity with little disruption. With low noise levels and high safety standards, it addresses modern industrial needs efficiently.

FAQs of Heavy Duty Hydraulic Pump:

Q: How do I install the Heavy Duty Hydraulic Pump in my hydraulic system?

A: Installation is straightforward thanks to its foot-mounted design and threaded BSP connections. Simply secure the pump on a stable base, connect the inlet and outlet with 1-inch pipes, and ensure the power supply matches its 220240 V requirement. The pumps automatic suction and self-priming features simplify the initial setup process.Q: What types of fluids are compatible with this pump?

A: This pump is designed for hydraulic oil and light mineral oil, ensuring optimum performance and long seal life. Using other fluids may compromise sealing integrity and overall efficiency, so its recommended to adhere to the specified fluid types.Q: When is regular maintenance needed for this pump?

A: Routine checks should be performed according to your operations intensity. Thanks to its easy-maintenance design and high-performance nitrile seals, maintenance is minimaltypically limited to periodic inspection of seals, connections, and electrical components after extensive use or every six months in continuous operations.Q: Where can this hydraulic pump be used most effectively?

A: It excels in industrial and agricultural environments including hydraulic systems, heavy machinery, construction projects, and any applications requiring reliable fluid transfer at high pressure and medium duty caliber. Exporter, manufacturer, supplier, and trader operations in India commonly use it for consistent, robust performance.Q: What process does the pump use to start suction and priming?

A: The pump features self-priming and automatic suction, enabling it to begin fluid movement without manual intervention. After connecting the power and fluid lines, it automatically generates suction up to 7 meters, minimizing setup time and effort.Q: What are the main benefits of using this pump in heavy-duty applications?

A: Users benefit from robust construction, high efficiency, corrosion resistance, and low noise operation. Its IP55 protection class and reliable seals ensure safe functionality in harsh conditions, while ISO 9001:2015 certification guarantees consistent quality and performance, maximizing uptime and productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email